Samfura

Bakin karfe dam fiber ko yadi ciki core conductive waya domin zafi yadudduka

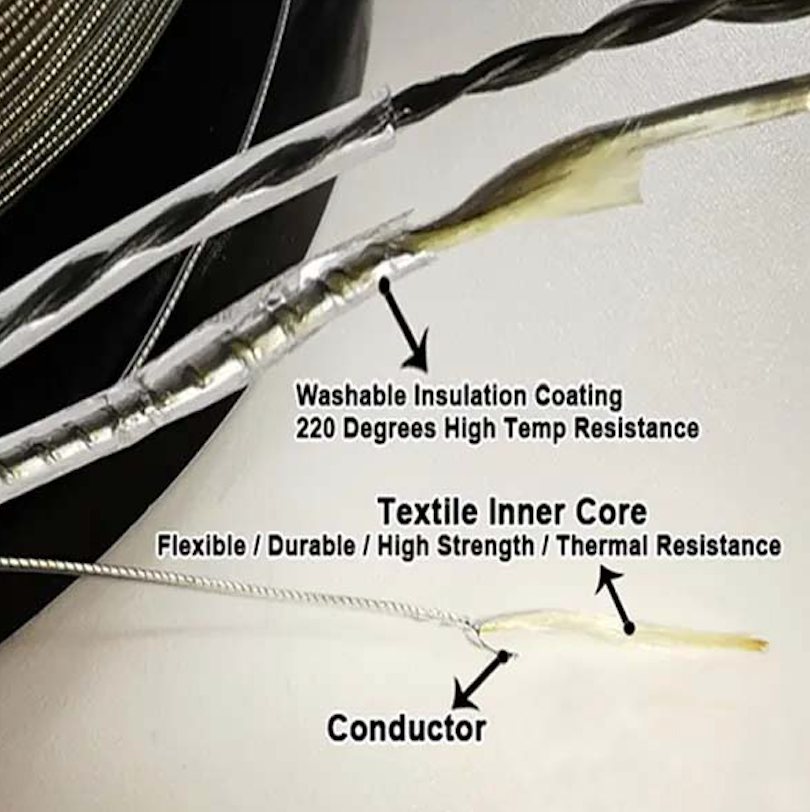

Bayanin Samfura

1-Bakin ƙarfe fiber tushen dam inda diamita na kowane mutum fiber ne 12µ ko 14µ. Adadin fibers yawanci daga kusan 200 zuwa sama da filaments 1500. Wannan yana ba ku dorewa wanda shine mafi nisa 'mafi kyawun aji'. Saboda kyawawan zaruruwan da aka yi amfani da su, waɗannan igiyoyi har yanzu suna zama sirara a faɗin diamita kuma don haka suna sassauƙa sosai wajen sarrafawa.

2-Muna rufe da fadi da kewayon ƙananan juriya ƙarin waya mai kyau da ƙananan igiyoyi tare da halaye masu ɗorewa da sassauƙa, na musamman na mu tare da ƙananan igiyoyi na yadi na ciki na iya ƙididdige juriya ta kowace mita da kuke buƙata kuma yana ba ku ƙarin sassauci a cikin ƙira amma har yanzu yana ba da mafi kyawu. sassauya-rayuwa fiye da kwatankwacin Cu-Cables. Dangane da m nannade gami wanda za a iya tinned, jan karfe, azurfa gami da dai sauransu, za mu iya samar da conductive resistant ko da kasa da 1 ohm / m micro igiyoyi da guda da stranded iri bisa ga abokin ciniki bukata.

Fa'idodin kebul na yadi na ciki na ciki

Juriya Lankwasawa

Saboda tsari da haɗuwa da kayan aiki, waya yana da kyakkyawan juriya na lankwasawa.

sassauci

Ƙananan igiyoyin igiyoyi suna amfani da foil na ƙarfe na bakin ciki sosai a matsayin jagora, wanda ke gane babban sassauci.

Ultra-Fine

Bayan extrusion mu micro USB thinest iya zama zuwa 0.35mm.

Ƙarfin Ƙarfin Ƙarfi

Muna amfani da Aramid / Liquid Crystal Polymer fibers da injiniyan kai babban filayen fasaha.

Babban zafin jiki. Juriya

Muna amfani da aramid ko bakin karfe fiber dam filaments don zaruruwa, high temp resistant daga 230 digiri zuwa 580 digiri don zabi.

Ƙarshe & shafa

A cikin duniyar ku, akwai galibin buƙatu don lacquering na filaments na mutum ɗaya ko kuma shafi gabaɗayan extrusion akan cikakken kebul. Hakanan zamu iya yin hakan, abubuwan da ke cikin mu sun haɗa da FEP, PFA, PTFE, TPU da sauransu.

BAYANIN JACKET INSULATION

| Extrusion | TPE | FEP | MFA |

| Melting Point | 205°C | 255°C | 250°C |

| CAiki na yau da kullun Tdaular | 165°C | 205°C | 225°C |

Bakin Karfe Fiber Bundles

Textile Inner Core Micro Cable Constructions

Tushen Tufafi Mai Dumama

Bakin karfe ya haɗa jeri daban-daban na juriya don bayanin ku.

| Diamita (um) | Filaments | Ƙarfi (cN) | Nauyi (g/m) | Tsawaitawa (%) | Ayyukan aiki (Ohm/m) |

| 8 | 1000F x 1 | 69 | 0.420 | 1.10 | 16 |

| 8 | 1000F x 2 | 108 | 0.850 | 1.10 | 8 |

| 12 | 100F x 1 | 24 | 0.110 | 1.10 | 59 |

| 12 | 100F x 2 | 41 | 0.190 | 1.10 | 38 |

| 12 | 100F x 3 | 69 | 0.280 | 1.10 | 22 |

| 12 | 257f 1 | 59 | 0.260 | 1.10 | 27 |

| 12 | 275x 2 | 75 | 0.540 | 1.10 | 14 |

| 12 | 275x 3 | 125 | 0.780 | 1.10 | 9 |

| 12 | 275x 4 | 130 | 1.050 | 1.10 | 7 |

| 12 | 275F ku 5 | 160 | 1.300 | 1.10 | 5 |

| 12 | 275x 6 | 180 | 1.500 | 1.10 | 4 |

| 12 | 1000F x 1 | 100 | 0.950 | 1.10 | 7 |

| 12 | 1000F x 2 | 340 | 1.900 | 1.10 | 4 |

| 14 | 90f x2 | 46 | 0.190 | 1.10 | 44 |

| 14 | 90f 1 | 25 | 0.110 | 1.10 |

Yadi na ciki core conductive waya daban-daban juriya jeri

| Mai Gudanarwa na waje | Textile Inner Core | Diamita mm | Gudanarwa ≤Ω/m |

| Copper 0.08mm | 250D Poyester | 0.20± 0.02 | 6.50 |

| Copper 0.10mm | Polyester 250D | 0.23± 0.02 | 3.90 |

| Copper 0.05mm | 50D Kuraray | 0.10± 0.02 | 12.30 |

| Copper 0.1mm | 200D Dinima | 0.22± 0.02 | 4.00 |

| Copper 0.1mm | Polyester 250D | 1*2/0.28 | 2.00 |

| Copper 0.1mm | 200D Kevlar | 0.22± 0.02 | 4.00 |

| Copper 0.05mm | Polyester 50D | 1*2/0.13 | 8.50 |

| Copper 0.05mm | Polyester 70D | 0.11 ± 0.02 | 12.50 |

| Copper 0.55mm | Polyester 70D | 0.12 ± 0.02 | 12.30 |

| Copper 0.10mm | Auduga 42S/2 | 0.27± 0.03 | 4.20 |

| Copper 0.09mm | Polyester 150D | 0.19± 0.02 | 5.50 |

| Copper 0.06mm | Polyester 150D | 0.19± 0.02 | 12.50 |

| Tin Copper 0.085mm | 100D Kuraray | 0.17± 0.02 | 5.00 |

| Tin Copper 0.08mm | 130D Kevlar | 0.17± 0.02 | 6.60 |

| Tin Copper 0.06mm | 130D Kevlar | 0.16 ± 0.02 | 12.50 |

| Tin Copper 0.10mm | Polyester 250D | 0.23± 0.02 | 4.00 |

| Tin Copper 0.06mm | Polyester 150D | 0.16 ± 0.02 | 11.6 |

| Tin Copper 0.085mm | 200D Kevlar | 0.19± 0.02 | 5.00 |

| Tin Copper 0.085mm | Polyester 150D | 0.19± 0.02 | 6.00 |

| Azurfa Copper 0.10mm | Polyester 250D | 0.23± 0.02 | 3.90 |